Tube Inspection

Heat Exchanger Tube Testing Equipment

For the inspection of heat exchanger tubes different eddy current techniques can be applied. The choice of the particular eddy current technique and sensor type depends on the tube material, type and volume of the defects to be detected as well as on possible perturbations by e.g. changes of the tube dimensions in the tube expansion. The following scheme gives an overview about applicable eddy current techniques.

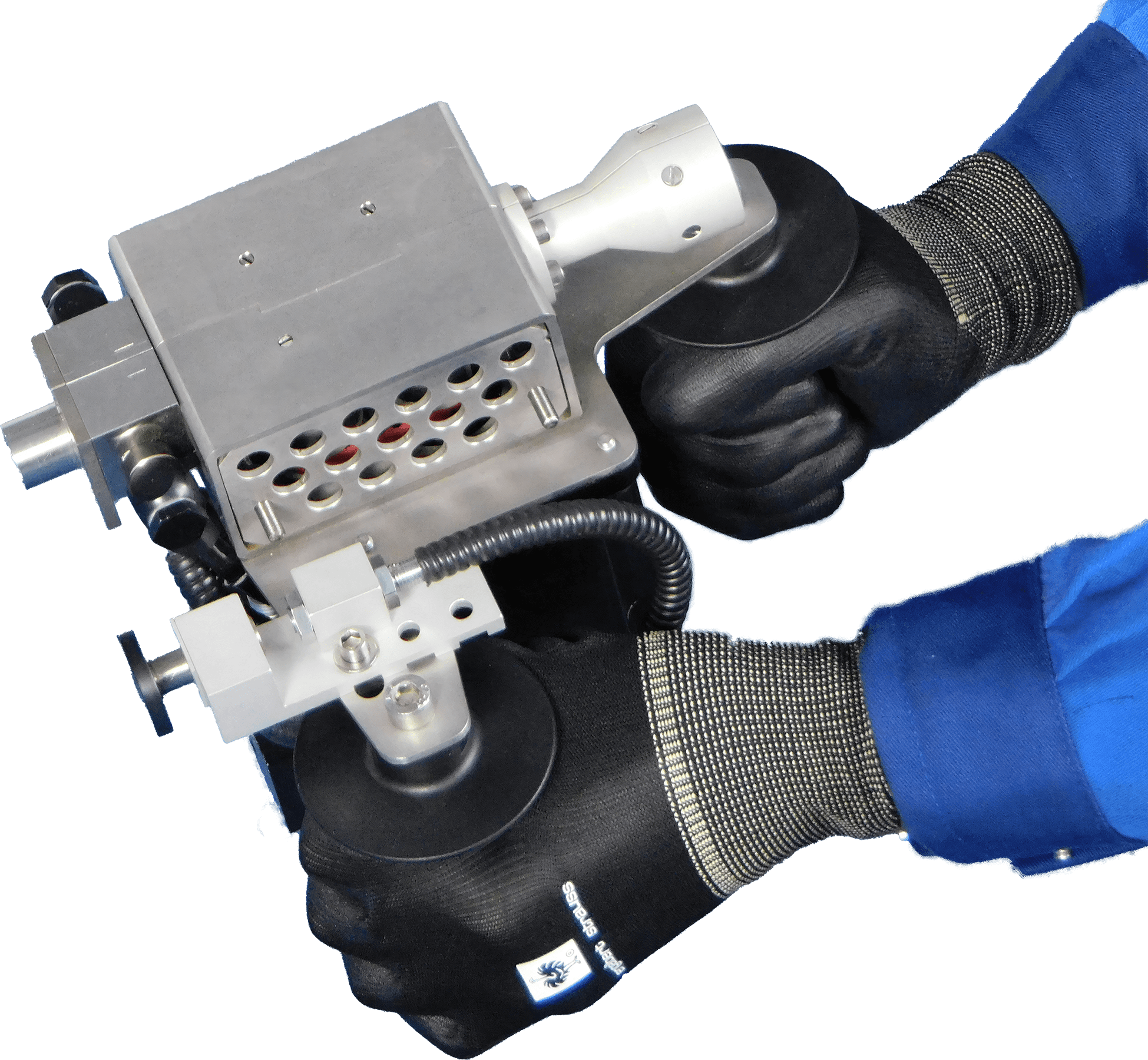

Automatic Hand-Held Probe Pusher Puller

For inspection of big numbers of tubes or for inspection requiring an accurate evaluation of defect positions the application of probe pusher puller has an vital advantage.

The hand-held probe pusher puller system developed by TMT Test Maschinen Technik GmbH allows a fast, convenient and accurate probe handling. All drive functions are controlled from the eddyMax system. Optionally the probe insertion can be supported by compressed air allowing an operation even under hard conditions.

The TubeMax® Software

The TubeMax software is developed for signal data acquisition and online or offline signal data analysis of differential and absolute signals in eddy current inservice tube inspection applications. The main TubeMax® software features are:

- user configuration of inspection frequencies and number of differential, absolute and mixer channels

- user configuration of the screen display for impedance and chart windows

- input, edit, storage, read and delete of phase versus defect depth or amplitude versus defect depth calibration curves for inservice tube inspection according to ASME-Code or user selected requirements

- determination of master evaluation and confirmation channels

- automatic phase and sensitivity adjustment of reference signals

- automatic online (direct after data acquisition) or offline signal evaluation of up to 1000

indications for all selected frequency channels - direct automatic storage of inspection result with code for internal/external defect, defect

position and signal amplitude to the selected tube coordinate (in combination with WinDevos software)