Pipeline Scanner Systems

Unpiggable Pipeline In-Line Scanner Systems

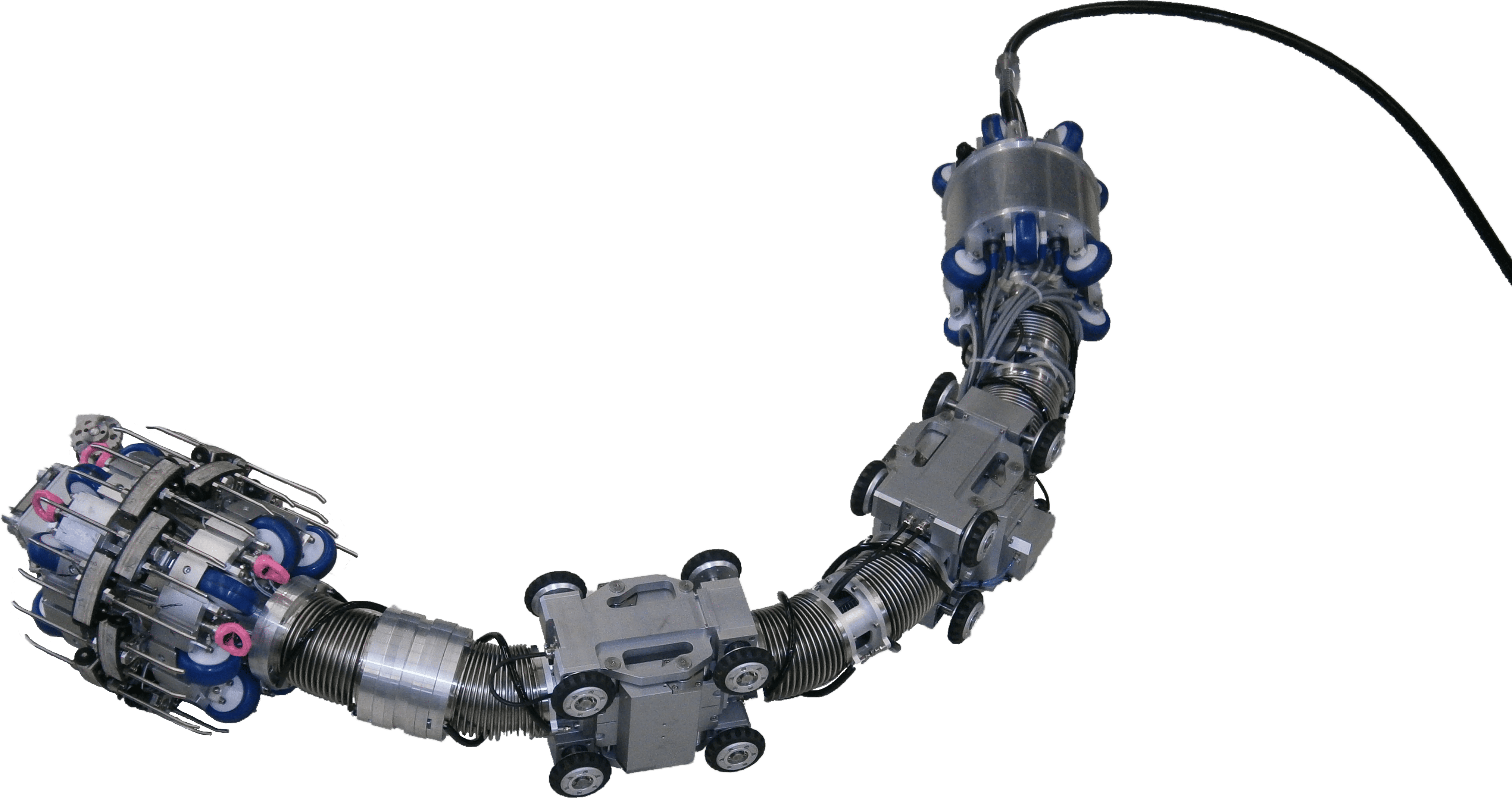

PLM & PLS Scanner Systems

Unpiggable Pipline In-Line Scanner Systems with SLOFEC®

Unpiggable Pipeline In-Line Scanner Systems (PILS) are highly specialized technologies used in the oil and gas industry to inspect pipelines, particularly those that are difficult or impossible to access using conventional methods. The term “unpiggable” refers to pipelines that cannot be cleaned or inspected using traditional “pigs,” which are pipeline inspection devices, due to factors such as their size, design, branching, or other constraints.

PILS systems have been developed to address this challenge and enable the inspection of pipelines that were previously considered hard to access. They utilize advanced technologies such as ultrasound, magnetic particle testing, eddy current testing, and other methods to capture the condition of the pipeline and detect potential defects. These systems can be installed in existing pipelines without requiring extensive dismantling or modification of the pipeline.

Some of the benefits of Unpiggable PILS systems include:

- Enhanced Inspection Capabilities: PILS systems allow for detailed inspection of pipelines that would be inaccessible using conventional methods, leading to improved monitoring and maintenance.

- Extension of Pipeline Lifespan: Regular inspection and identification of defects through PILS systems can lead to timely interventions, extending the lifespan of the pipeline and avoiding costly repairs.

- Reduction of Environmental and Safety Risks: Precise monitoring of pipelines helps minimize leaks and other potential hazards, reducing environmental and safety risks.

- Cost Savings: The use of PILS systems can avoid expensive and labor-intensive methods like pipeline dismantling for inspection purposes.

It’s important to note that the development and implementation of Unpiggable PILS systems are technically challenging and require thorough planning and expertise. However, technological advancements have significantly enhanced the industry’s ability to inspect and maintain pipelines, while simultaneously elevating environmental and safety standards.